I do not have a pyrometer and I am heading to the dyno tomorrow. Since I will be tuning it myself I want to enable lean protection but am not sure what settings to use.

I am trying to understand the factors that play a role in damaging the engine due to leaning out.

I think: lean = hot -AND- hot = melted exhaust valves

What I don't understand is why 14.7 would be good while driving around, yet dangerous when full throttle. What's the deal?

Does ?

A) RPM affect the safe A/F?

B) Engine load affect the safe A/F?

C) Manifold pressure affect the safe A/F?

Really I just want to know for certain that I can leave the values defaulted and safely tune my car.

Requisite stuff:

2003 RSX Type-S (Mostly stock)

I/H/E, RBC, K-PRO SN# 37820-PRB-A06 2068-609057

How lean is too lean, how to know? Lean Protection Settings?

I'm not an expert, so I can't give you a complete answer, but I can help a bit.

First, for all intents and purposes, manifold pressure = engine load. Second, what makes it safe to run leaner at part throttle is that there's less intake charge. It's generating less heat simply because there's less material to burn.

Hopefully that helps you understand at least a bit better :)

First, for all intents and purposes, manifold pressure = engine load. Second, what makes it safe to run leaner at part throttle is that there's less intake charge. It's generating less heat simply because there's less material to burn.

Hopefully that helps you understand at least a bit better :)

I'm going completely by memory.

Cruise and no-load 14.7 is used because its an efficient burn that limits exhaust emissions.

I personally run 15.5, but NOx emissions are higher

Under heavy load 14.7 is fine if you want to burn a hole in the piston.

The more load you have on the engine, the more fuel to air you want.

If you have an N/A motor, just check the lean protection 1 box and use the default values. If you hit lean cut on transition from part to full throttle, try adjusting the trigger time, and then tune it out once you get a datalog without hitting cut on transition

Cruise and no-load 14.7 is used because its an efficient burn that limits exhaust emissions.

I personally run 15.5, but NOx emissions are higher

Under heavy load 14.7 is fine if you want to burn a hole in the piston.

The more load you have on the engine, the more fuel to air you want.

If you have an N/A motor, just check the lean protection 1 box and use the default values. If you hit lean cut on transition from part to full throttle, try adjusting the trigger time, and then tune it out once you get a datalog without hitting cut on transition

Thanks... That's more or less what I ended up doing.

I was talking to a tuner who works at the shop where I dyno'd. He said that they have the best results tuning for power at 13.3:1. then playing with timing and fuel you'll end up anywhere from 12.9 to 13.1.

Since we started with the same basemap that I had been using lean out wasn't too much of a problem. I found that there are several conditions that cause the motor to lean cut at different points while on the dyno and running with it disabled while keeping an eye on both the built-in and the tail-pipe A/F meters seems to have worked out the best.

By the way, tuning the last three columns for max power is fairly straight forward... Tuning everything else seems almost impossible.

That being that, I believe that there simply isn't any way to get around it; I need to get a pyrometer before tuning part throttle.

Since we started with the same basemap that I had been using lean out wasn't too much of a problem. I found that there are several conditions that cause the motor to lean cut at different points while on the dyno and running with it disabled while keeping an eye on both the built-in and the tail-pipe A/F meters seems to have worked out the best.

By the way, tuning the last three columns for max power is fairly straight forward... Tuning everything else seems almost impossible.

That being that, I believe that there simply isn't any way to get around it; I need to get a pyrometer before tuning part throttle.

The way I'd go about tuning part throttle is to pick a speed at each of the RPM points in the fuel/ign table and set your cruise control to hold it there. Then get your AFR to where you want it, then tune ignition until the injector pulse width is at the smallest number you can get it to. Then, generally, pull half a degree of spark timing back out from that point for safety.

More difficult if you don't have cruise control - but still. That's how I do it.

More difficult if you don't have cruise control - but still. That's how I do it.

I just take a look on my previous data logings and I found that I have a 7 minutes run with cca 16:80 AFR, so very very lean. my setup is PRA ECU + PLX wideband (used only for datalog, ELD pin 15) + K20A2 factory map as my engine is standard.

I didn't see that 16:00 AFR value on the PLX display cause I would stopped the engine imediately!

The other data logs show normal AFR readings. I never touch the standard factory kal parameters, could this be a reading error?

I also checked the primary lambda (narrow band on PRA ECU) voltage and seems to be ok. The voltage have same values as in the others calibrations but the AFR figure dont't.

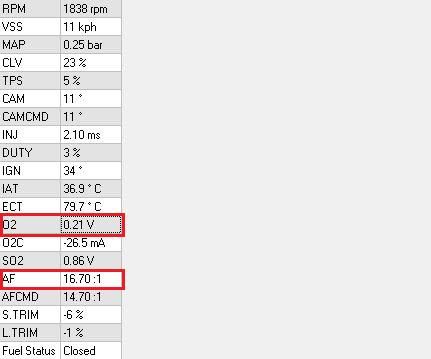

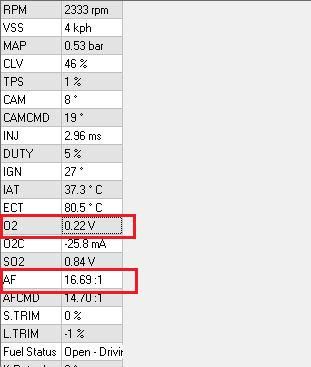

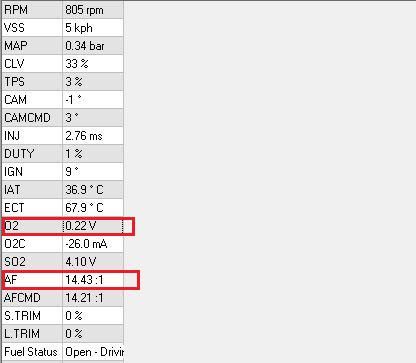

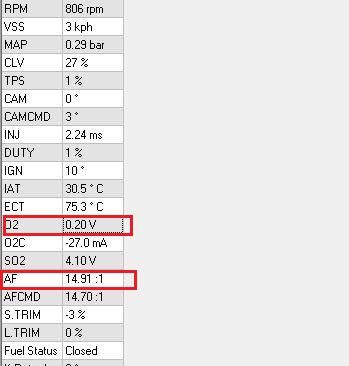

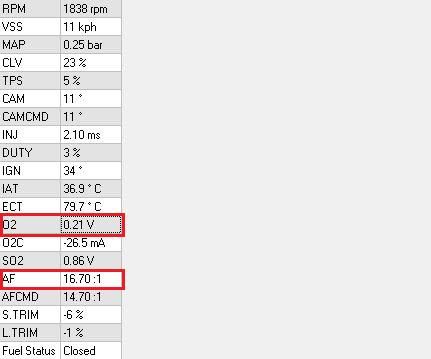

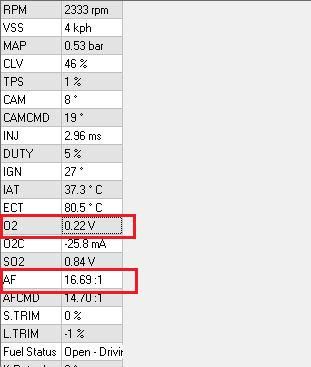

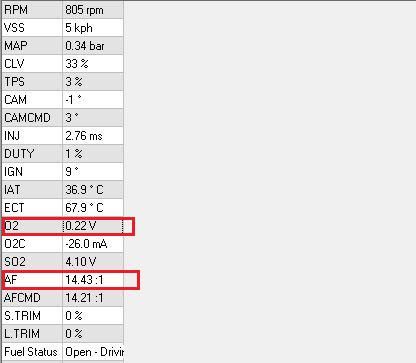

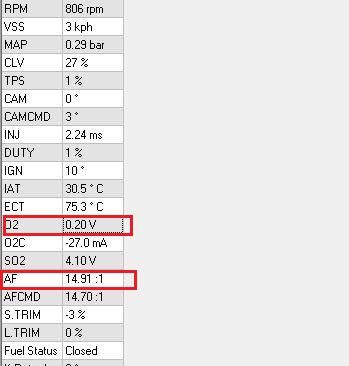

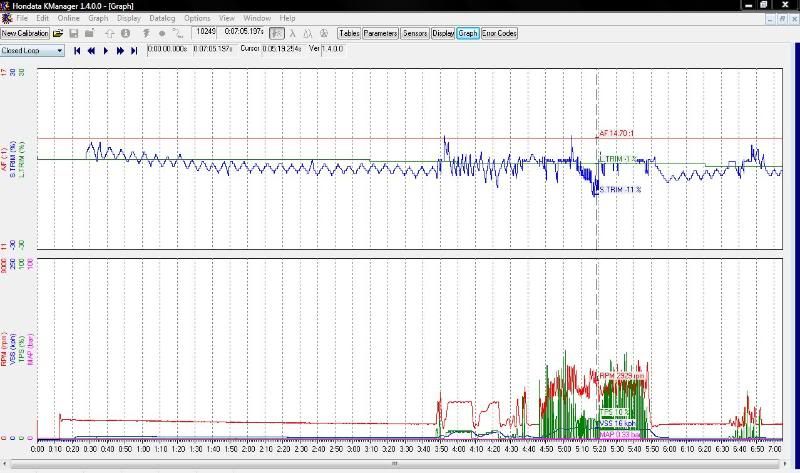

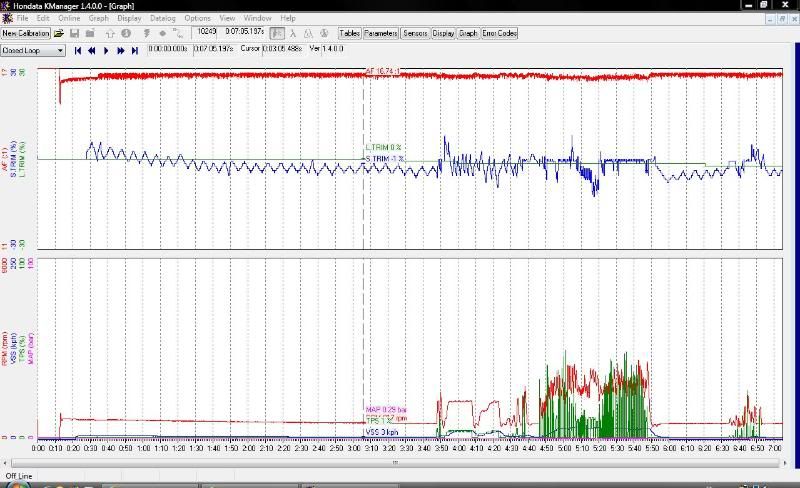

As you see in this pictures the AFR is arround 16:70 , but the main narrowband lambda used by ECU is arround 0,21V.

in the other calibrations arround same 0,21V (main narrowband lambda used by ECU) I have arround 14:77 , 14:44 etc AFR

here is the datalog file, please check the main O2 voltage. seems to be OK but the AFR ratio is wrong:

http://www.mediafire.com/?95gfwu4a5rhlvzn

Could this be a reading error of the PLX module as on the very next datalog the AFR figure returned to normal?

If was the real 16:80 AFR value could I damage the engine on a 7 minutes run where I hit cca 3300 rpm max?

many many thanks

I didn't see that 16:00 AFR value on the PLX display cause I would stopped the engine imediately!

The other data logs show normal AFR readings. I never touch the standard factory kal parameters, could this be a reading error?

I also checked the primary lambda (narrow band on PRA ECU) voltage and seems to be ok. The voltage have same values as in the others calibrations but the AFR figure dont't.

As you see in this pictures the AFR is arround 16:70 , but the main narrowband lambda used by ECU is arround 0,21V.

in the other calibrations arround same 0,21V (main narrowband lambda used by ECU) I have arround 14:77 , 14:44 etc AFR

here is the datalog file, please check the main O2 voltage. seems to be OK but the AFR ratio is wrong:

http://www.mediafire.com/?95gfwu4a5rhlvzn

Could this be a reading error of the PLX module as on the very next datalog the AFR figure returned to normal?

If was the real 16:80 AFR value could I damage the engine on a 7 minutes run where I hit cca 3300 rpm max?

many many thanks

Don't really understand...

So I opened the datalog and everything looked perfect. You had a constand 14.70:1 AFR.

If you had a problem, all I can recommend is the obvious stuff like making sure that the A/F sensor is configured properly in K Manager.

If you had a problem, all I can recommend is the obvious stuff like making sure that the A/F sensor is configured properly in K Manager.

Re: Don't really understand...

many thanks!taohawaii wrote:So I opened the datalog and everything looked perfect. You had a constand 14.70:1 AFR.

If you had a problem, all I can recommend is the obvious stuff like making sure that the A/F sensor is configured properly in K Manager.

...so If I look at this log using the main lamda sensor (narrowband on PRA ECU) the AFR is 14,7:1 flat

but if I look at the same log using the PLX wideband the AFR is about 16,8:1 .

is this a proof that I'm dealung with a reading error on this log? I repeat on all other logs the AFR figures are right...

...and I can't enable lean protection I don't know why...

thanks again!

-

rick_rabies

- Posts: 12

- Joined: Mon Aug 10, 2009 7:58 pm

not to hijak but. i have a similar problem

i have kpro open and put in open loop.

idles at 16ish AFr.

i add %10 fuel. idle sounds changed but AFR stays in teh 16s...

i add another 10% and it barely touches the 15s but stays in teh 16s...

any suggestions?

o2 wiring mixed up?

eg/k24a2 and using a kmanager k24a2 cal...imagine that...

520cc injectors. bolt ons

i have kpro open and put in open loop.

idles at 16ish AFr.

i add %10 fuel. idle sounds changed but AFR stays in teh 16s...

i add another 10% and it barely touches the 15s but stays in teh 16s...

any suggestions?

o2 wiring mixed up?

eg/k24a2 and using a kmanager k24a2 cal...imagine that...

520cc injectors. bolt ons

best guess

I am a little lost on the first post... My thoughts were along the lines of whatever O2 sensor you have configured when you datalogged determines the voltage range (and values recorded) for the A/F calculations. The voltage seems the important number. If you change your O2 sensor configuration and playback the log again, it should be incorrect. (I guess, this is my ass talking here.)

It seems as this is too simplistic an answer and thus I most likely don't understand your problem at all.

As for the second post, if your AFR is not changing when you add 10% fuel then your primary wide band is not working.

I had the same problem. Somehow I got my primary and secondary mixed up. (Not the wiring, that's impossible. I was just confused.) I had placed the sensor that I thought was the secondary in a CEL eliminator. When I went to the dyno I kept dumping crazy fuel into the motor with no changes. Then we put a tail pipe type wide band on and sure enough 10:1! Wow! (Not like you couldn't smell it...)

Anyway needless to say I just put both sensors straight into the race header and the problem was solved. (I also selected the feature that disables the OBD II sensors).

The only other explanation that I can fathom is that you could be accidentaly changing the wrong fuel table.

It seems as this is too simplistic an answer and thus I most likely don't understand your problem at all.

As for the second post, if your AFR is not changing when you add 10% fuel then your primary wide band is not working.

I had the same problem. Somehow I got my primary and secondary mixed up. (Not the wiring, that's impossible. I was just confused.) I had placed the sensor that I thought was the secondary in a CEL eliminator. When I went to the dyno I kept dumping crazy fuel into the motor with no changes. Then we put a tail pipe type wide band on and sure enough 10:1! Wow! (Not like you couldn't smell it...)

Anyway needless to say I just put both sensors straight into the race header and the problem was solved. (I also selected the feature that disables the OBD II sensors).

The only other explanation that I can fathom is that you could be accidentaly changing the wrong fuel table.